Himanshu’s ideas have a deep foundation—he’s not just thinking about the end product; he’s thinking about the entire process. From farm to loom to store shelves, how can we harness our indigenous practices—improve on them, in fact—to create something that isn’t harming us or the environment?

One place where he’s finding the answers is biodynamic farming, an organic farming movement rooted in cosmology that was developed in 1924 by Austrian philosopher and social reformer Rudolf Steiner. Himanshu demurs when called a farmer himself.

“I managed to learn a bit at the farm of Sarvdaman Patel—he’s kind of an icon in biodynamic farming—and then I applied it [to our processes] with my colleague Adheep AK, who leads our natural dyeing developments. Eventually it means the soil might become high in minerals, which means better natural indigo, or maybe it improves the staple length of cotton. We have a small piece of land in Kutch and also friends and collaborators who are actually farmers, with whom we are able to try these experiments.”

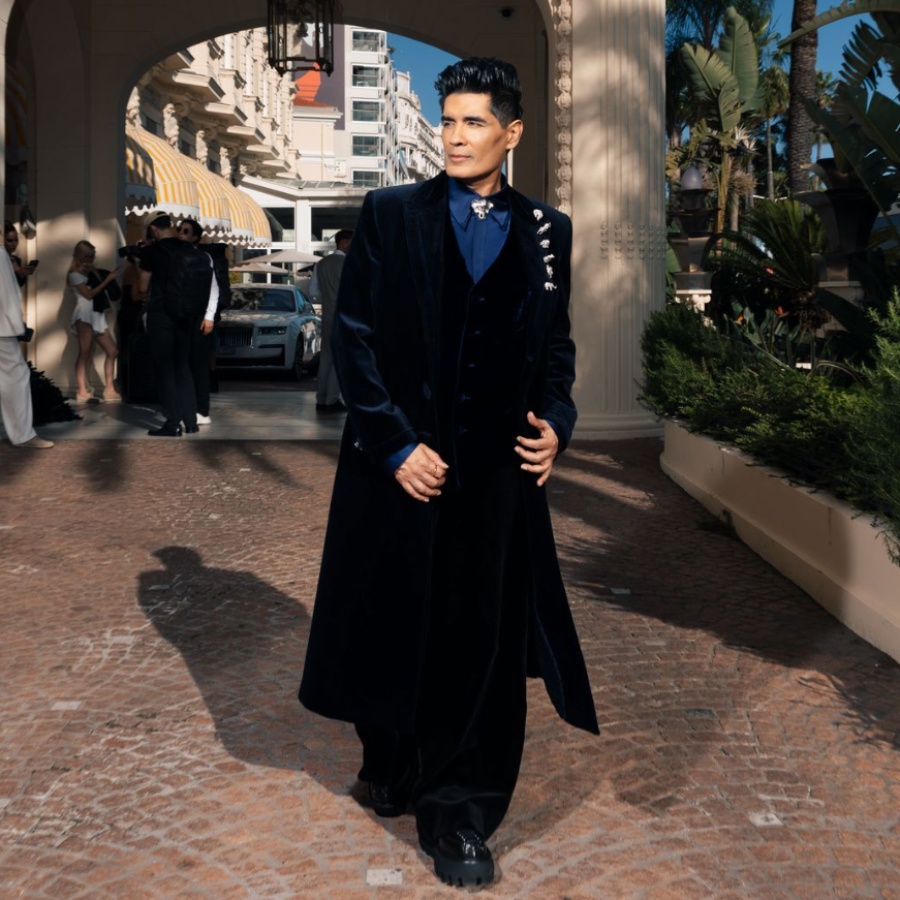

The technique has some associations with mysticism, so I ask Himanshu if he’s a believer in things like crystals or astrology. The 45-year-old somberly shakes his head, adding, “But I do believe in the benefits of making things by hand. The slow processes, like, say, cooking at home, have a different energy compared to fast ones.” Internet boyfriend Dev Patel and Formula One racer Lewis Hamilton seem to agree; both were recently spotted looking ultra comfortable in the brand’s slouchy, India-via-Japan looks. Patel was in a shibori-dyed shirt, and Hamilton in a pair of shibori bermuda shorts.

The NIFT Gandhinagar graduate has a long-standing fascination with indigo, especially its interactions with denim. He has consulted with brands like Levi’s and Diesel, where he worked with Italian fashion magnate Renzo Rosso, and even co-founded his own denim brand, Korra, that ran for a while. Himanshu learnt the nuances of natural dying over 15 years ago in Auroville from Jesus Ciriza Larraona, a pioneer of the technique.

Fast forward to the present, and the centrepiece of the 11.11/eleven eleven store in Okhla is a vat of indigo in which customers are invited to dip a piece of cloth. The brand has 30 more terracotta vats at their workshop in New Delhi, some of which are over a decade old, and which can ferment 5,000 litres of the golden-green natural dye that turns bright blue upon exposure to air. “What fascinates me is that a vat of indigo is a living organism that can survive generations,” he says. Like sourdough? “It means you never throw the water away. The other fascinating thing is that you don’t need heat—it’s a cold dyeing process.”

Last year at the Serendipity Art Festival, Goa, the brand presented their newest development: pure indigo paste that can be used for printing rather than dyeing. Via an immersive installation, visitors were invited to dip their feet into the paste and leave their footprints on a piece of white cloth.

In some ways, it was indigo that brought Himanshu back to India after he spent five years in Milan, where he was completing his Master’s at Domus Academy before going on to work with companies like Change Design and Diesel. Milan brought its own learnings: “‘Made in Italy’ stands for something. What they offer is deep-rooted values and craftsmanship. It’s about appreciating the people and the materials, it’s about passion for who you are and what you do, which is what I felt was missing in India,”

Rather than staying back, Himanshu brought those lessons home to New Delhi. “Instead of treating India as a place where people come to make cheaper things, I wanted to find the roots of our indigenous practices. There is so much depth and history. The question is: how do we nurture ourselves with our own value system?”

It’s this that drives Himanshu’s vision of building 11.11/eleven eleven into a global brand. Right now, their breezy, bandhani-spotted shirts, ultra-soft cotton T-shirts, and slouchy blazers—all in soothing natural tones—are already available in over 20 countries from USA and Japan to Europe, Hong Kong, and Australia. While the current emphasis is on clothes and the one-off pair of patchwork Converse, Himanshu hints at research being done in areas like bamboo, grass materials, terracotta, and other fields that are closely linked to their work in textiles. He says, “We consume Western brands every day, in all forms, throughout our lives. There’s no Indian brand that is consumed across the globe. There are more than 70 lakh artisans across the country, so it’s not like the scale is impossible.”

But wherever the brand’s pieces go, a chip embedded in the button, along with unique serial number on the garment tag, will help you trace the path it has taken to get to you. Whether it’s a monastic linen dress that was woven in Kutch and then dyed in Auroville or a pair of dhoti-like olive-green trousers that were woven in Gondal, Gujarat, using cotton from Tamil Nadu and then tailored in Delhi, you’ll know that an 11.11/eleven eleven garment is firmly made in India.